Landlord heating responsibilities…

Landlord heating responsibilities…

Warm tenants are happy tenants. But if you’re a landlord; there’s more than your tenant’s happiness to consider when it comes to heating your rental property.

Unfortunately, faulty boilers and heating systems can cause serious problems for landlords.

At worst, dangerous gas appliances pose an immediate threat to life in terms of risk of fires; explosions; and carbon monoxide poisoning.

Every year there are around 60 deaths from accidental carbon monoxide poisoning in England and Wales. Less dangerous, but nevertheless costly problems include damage to property caused by escaped water.

But as well as these safety and financial implications, there are legal ones too.

As a landlord, you have a legal responsibility to provide and maintain the heating and hot water for your tenants. And to ensure your property is safe, and energy efficient.

In this blog, we take a closer look at landlord heating responsibilities; so that you can be sure that you understand what your obligations are.

What does the law say?

The key legal obligations on landlords when it comes to heating are that:

1. Landlords must provide access to heating and hot water – The Landlord and Tenant Act 1985;

Under section 11 of the Landlord and Tenant Act 1985; as a landlord you are responsible for keeping the following in repair and proper working order – supply of:

Under section 11 of the Landlord and Tenant Act 1985; as a landlord you are responsible for keeping the following in repair and proper working order – supply of:

- water;

- gas;

- electricity;

- sanitation (including basins, sinks, baths and toilets);

- heating;

- hot water.

Unless your tenant has damaged the facilities; it’s your responsibility to ensure that the property has heating and hot water at all times.

It’s a hazard to have no heating and hot water, especially in winter. And if no alternative source is provided.

A 2016 report by The Energy Saving Trust found that 48% of renters are finding home heating a struggle. And frankly, that’s not good enough.

Minimum acceptable standards are that bedrooms should be able to maintain at least 18°C; and 21°C in living rooms when the temperature outside is minus 1°C.

Local Authorities can force you to upgrade your property under the Housing Act 2004.

2. Landlords are responsible for repairs, and must keep the heating in proper working order

As a landlord, it’s your responsibility to maintain and repair the heating in your rental property; under Section 11 (c) of the Housing Act 1985.

As a landlord, it’s your responsibility to maintain and repair the heating in your rental property; under Section 11 (c) of the Housing Act 1985.

Some landlords try to avoid this responsibility by including clauses in their tenancy agreements. But such clauses will be void.

Your tenant is responsible for reporting any issues with the heating and hot water supply to you. And it’s your duty to respond within a reasonable time (see below).

3. Landlords must react to any heating problems that may occur within a few days after the tenants’ notification

Obviously, you can’t be liable to carry out any repairs until you’ve been told about the issue by your tenant.

Obviously, you can’t be liable to carry out any repairs until you’ve been told about the issue by your tenant.

But once they have notified you of an issue, you need to carry out the repair within a ‘reasonable time’.

There is no definition of what constitutes a ‘reasonable time’. Instead, several factors will be taken into account, for example:

- the extent of the disrepair;

- what time of year it is;

- the age (and health) of residents living in the property;

- availability of replacement parts;

- Whether any alternative heat sources have been provided.

You’ll need to react faster to problems with the heating or hot water supply; when this affects families with small children.

Failure to respond to notice of disrepair means that you will be breaching your tenancy agreement on two fronts; keeping the property in repair AND free from hazards (see below).

4. Landlords must keep the property free from hazards

Maintaining central heating and hot water is an important part of keeping your property free from hazards.

Maintaining central heating and hot water is an important part of keeping your property free from hazards.

The Housing Health & Safety Rating System (HHSRS) introduced by the Housing Act 2004 came into effect on April 6th 2006.

The HHSRS provides guidance about hazards under section 9 of the Housing Act 2004.

The underlying principle of the HHSRS is that any residential premises should provide a safe and healthy environment for any potential occupier or visitor.

To satisfy this principle, your rental property should be designed; constructed; and maintained; with non-hazardous materials and should be free from both unnecessary and avoidable hazards.

The HHSRS introduced 29 categories of housing hazard. In terms of heating, you should be aware of the following particular hazards:

The HHSRS introduced 29 categories of housing hazard. In terms of heating, you should be aware of the following particular hazards:

- Physiological hazards:

- damp and mould growth;

- excess cold or heat;

- asbestos;

- carbon monoxide and fuel combustion products;

- uncombusted fuel gas;

- Infection hazards

- hygiene, Sanitation and Water Supply

- sanitation and drainage

- Water supply

- Accident hazards

- Fires, Burns and Scalds

- Electrical hazards

- Fire

- Flames

- Explosions

- Position and operability of amenities

5. Landlords must arrange an annual gas safety check of all gas appliances in the property

Under the Gas Safety (Installation and Use) Regulations 1998; as amended by the Gas Safety (Installation and Use) (Amendment) Regulations 2018; you are under a statutory duty for the safety of your tenants in relation to gas safety.

Under the Gas Safety (Installation and Use) Regulations 1998; as amended by the Gas Safety (Installation and Use) (Amendment) Regulations 2018; you are under a statutory duty for the safety of your tenants in relation to gas safety.

By law you must:

- Repair and maintain gas pipework, flues and appliances in safe condition;

- Ensure an annual gas safety check on each appliance and flue;

- Keep a record of each safety check.

Annual Gas Safety checks are vital because if any of your gas appliances have been improperly fitted; repaired; or maintained; or any of their vents; flues; or chimneys have become blocked; they can pose a risk to your tenant’s life.

Dangerous gas appliances pose risk of gas leaks; fires and explosions; and carbon monoxide poisoning.

If any of your gas appliances aren’t burning their fuel as they should; they can produce a highly poisonous gas called carbon monoxide (CO). This gas is responsible for around 60 deaths per year in England and Wales.

Thankfully all these dangers can be easily avoided with a gas safety check once a year; by a Gas Safe registered engineer.

Only Gas Safe registered engineers can legally fit, fix, and service gas appliances. This requirement ensures that engineers who are working on gas hold valid and current qualifications.

Rest assured, all our engineers at The Heating People are Gas Safe registered.

What happens during a Gas Safety check for landlords?

During a gas safety check, our engineers will check that your appliances are:

During a gas safety check, our engineers will check that your appliances are:

- Properly set and adjusted so the gas burns correctly;

- Are suitable for the room it’s located in;

- Is physically stable, securely fitted and properly connected to the gas pipework.

We will also check that:

- There’s an adequate and permanent air supply that’s suitable for the appliance installed;

- All safety devices are functioning properly;

- Any flues, chimneys and air vents are operating correctly.

This can be extended to a full gas installation safety check, in which we will:

- Check the installation is in good condition by visually inspecting the pipework as far as reasonably practicable;

- Test the gas pipework to make sure there are no leaks.

When we have finished the safety checks, we provide you with a Landlord Gas Safety Record.

You’ll then be able to give a copy of this record to your tenants; so that they know that their appliances meet the appropriate safety standards.

The law on gas safety is enforced by the Health and Safety Executive (HSE). And there are severe penalties for non-compliance that can be imposed and deaths can result in manslaughter charges for landlords and agents.

Noncompliance is a criminal offence and courts can impose unlimited fines and custodial sentences.

6. Landlords should bleed the radiators at the start of the tenancy agreement. Once occupied, bleeding radiators becomes the tenants’ responsibility

In general, bleeding radiators is classed as day-to-day maintenance.

It’s good practice for you to make sure that the radiators are bled at the start of the tenancy. Tenants are responsible for bleeding them thereafter.

7. Landlords must ensure that their property meets the current minimum energy efficiency requirements

The Domestic Minimum Energy Efficiency Standard (MEES) Regulations set a minimum energy efficiency level for domestic private rented properties.

The Domestic Minimum Energy Efficiency Standard (MEES) Regulations set a minimum energy efficiency level for domestic private rented properties.

Landlords must ensure that their Energy Performance Certificates (EPCs) have a minimum rating of E.

An EPC rates your property’s energy efficiency from A (most efficient) to G (least efficient).

It’s valid for ten years, but if you don’t have one when you need one; you’ll face a fixed penalty notice of £200.

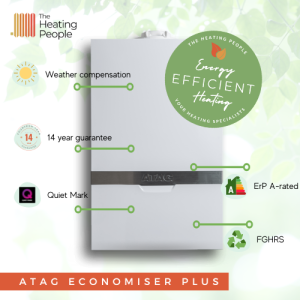

Modern boilers have an energy efficiency rating of at least 92% under the Boiler Plus regulations. But if you have an old heating system, it’s probably time to look at a replacement.

The government has recently published an energy efficiency proposal for the private rental sector. The energy performance standard of privately-rented properties will be raised to an EPC level C by 1 April 2025 for new tenancies and by 1 April 2028 for all tenancies.

Ypu might like to read our related blogs: 6 Top tips for buying a new boiler ; and How to choose an energy efficient boiler.

General tips for landlords

Once you’ve checked that you’re complying with all the relevant legislation; there are some general maintenance tips that you can follow.

These will help to avoid heating problems in your rental properties:

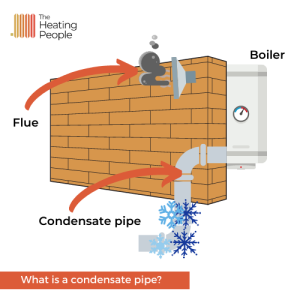

Tip: make sure external pipes are well insulated

If you have an external condensate pipe or an outside tap at your property; make sure it has a foam sleeve around it to prevent any issues when the temperatures drop.

If you have an external condensate pipe or an outside tap at your property; make sure it has a foam sleeve around it to prevent any issues when the temperatures drop.

A frozen condensate pipe will cause your boiler to shut down, meaning no heating and hot water for your tenants!

Tip: Look at your windows and doors

If you have old windows and doors on your property, it might be time to consider investing in an upgrade. Draughty windows and doors will make your property less energy efficient; and makes it harder to keep the property warm and dry.

Tip: Have your chimneys swept

If your property has a fireplace or log burner; you need to have your chimney swept at least once per year. This will ensure that carbon deposits are removed, minimising the risk of a chimney fire.

If your property has a fireplace or log burner; you need to have your chimney swept at least once per year. This will ensure that carbon deposits are removed, minimising the risk of a chimney fire.

Check extractor fans

The last thing that you want is mould and damp forming in your kitchens and bathrooms. Check that extractor fans are working properly to avoid warm air causing damp; mould; and mildew problems.

Encourage your tenants to use the heating

By encouraging your tenants to use the central heating (and leaving it on low if they go away for a few days) you’ll help to avoid damp forming, and pipes bursting. It also means that any issues can be reported to you promptly.

Test smoke alarms and CO detectors

It’s important that you test smoke alarms and CO alarms at least once per year. There must be a working smoke alarm on each floor of the property.

It’s important that you test smoke alarms and CO alarms at least once per year. There must be a working smoke alarm on each floor of the property.

A CO detector is required by law in any room with a solid fuel appliance.

Tip: Check your insurance

Ensure that you have a good insurance policy that is designed for landlords. This gives you the peace of mind that if a problem (such as a burst pipe) should arise, you’re covered.

Final thoughts…

We hope you’ve found this blog helpful.

If you want us to help you meet your responsibilities as a landlord; call one of our friendly team who will be happy to help.

Useful Links:

Government advice on renting and repairs

Shelter: Landlord and tenant responsibilities for repairs

If your heating is on, but you’ve got no hot water, it’s easy to get into a panic.

If your heating is on, but you’ve got no hot water, it’s easy to get into a panic. Forgive us for pointing out the obvious, but the first thing to do when your hot water goes off, is to check that your boiler’s working.

Forgive us for pointing out the obvious, but the first thing to do when your hot water goes off, is to check that your boiler’s working. Some hot water problems are not actually caused by a fault with your boiler. It could be that there is a problem with the supply of your electricity, gas and water.

Some hot water problems are not actually caused by a fault with your boiler. It could be that there is a problem with the supply of your electricity, gas and water. If your boiler’s hot water is controlled by a

If your boiler’s hot water is controlled by a  Similarly, to checking your timer, you should also check your boiler’s thermostat.

Similarly, to checking your timer, you should also check your boiler’s thermostat. Ah – the classic: have you tried switching it off and on again?!

Ah – the classic: have you tried switching it off and on again?! Another reason why you might not be getting any hot water is if there’s no pilot light on the boiler or the boiler pilot light keeps going out.

Another reason why you might not be getting any hot water is if there’s no pilot light on the boiler or the boiler pilot light keeps going out. If you have a sealed system or

If you have a sealed system or If your hot water has suddenly gone off when it’s freezing outside, there’s a good chance that your

If your hot water has suddenly gone off when it’s freezing outside, there’s a good chance that your  A leak somewhere in your heating system can cause the pressure to drop, which can stop your hot water from working.

A leak somewhere in your heating system can cause the pressure to drop, which can stop your hot water from working. If you’ve experienced a sudden problem with your hot water, it’s very unlikely you’ll need a new boiler. As you can see from above, there is often a cheap and quick fix to the dreaded no-hot-water situation.

If you’ve experienced a sudden problem with your hot water, it’s very unlikely you’ll need a new boiler. As you can see from above, there is often a cheap and quick fix to the dreaded no-hot-water situation. We hope that this guide has been useful in helping you to troubleshoot some of the simpler causes of having no hot water.

We hope that this guide has been useful in helping you to troubleshoot some of the simpler causes of having no hot water. 10 Tips for keeping your home warm this winter

10 Tips for keeping your home warm this winter You wouldn’t dream of driving your car without a valid MOT; and you should think of your

You wouldn’t dream of driving your car without a valid MOT; and you should think of your  The last thing you want when you’re paying to heat your home; is for all the

The last thing you want when you’re paying to heat your home; is for all the  As well as losing heat through gaps around your windows and doors; heat also escapes through your roof and walls through conduction and convection.

As well as losing heat through gaps around your windows and doors; heat also escapes through your roof and walls through conduction and convection. Insulating your water pipes is called ‘lagging’ and by sealing in heat; it saves energy and prevents pipes from freezing and bursting in the winter.

Insulating your water pipes is called ‘lagging’ and by sealing in heat; it saves energy and prevents pipes from freezing and bursting in the winter. If you have a hot water tank, check its insulation. Most hot water cylinders have some insulation; but if your tank has a jacket under 25mm thick, it could benefit from top-up insulation.

If you have a hot water tank, check its insulation. Most hot water cylinders have some insulation; but if your tank has a jacket under 25mm thick, it could benefit from top-up insulation. A common problem with radiators is that air can get trapped inside them; meaning that they don’t heat up properly. And your boiler will be working much harder to warm up your home.

A common problem with radiators is that air can get trapped inside them; meaning that they don’t heat up properly. And your boiler will be working much harder to warm up your home. Do you dry clothes by hanging them on your radiators? If so, stop! If you want your radiators to be able to heat your rooms effectively, they need to be unobstructed!

Do you dry clothes by hanging them on your radiators? If so, stop! If you want your radiators to be able to heat your rooms effectively, they need to be unobstructed! You’ve probably got a room (or rooms!) in your house that don’t get used as much as the others. If so, you’re wasting money on heating these rooms to the same temperature as the rooms you use all the time.

You’ve probably got a room (or rooms!) in your house that don’t get used as much as the others. If so, you’re wasting money on heating these rooms to the same temperature as the rooms you use all the time. If your radiators still have cold spots or feel cooler than usual; and bleeding them hasn’t worked, your heating system might need a

If your radiators still have cold spots or feel cooler than usual; and bleeding them hasn’t worked, your heating system might need a  Your

Your  Heating controls

Heating controls  Unfortunately, boilers don’t last forever. If you’ve noticed your boiler is struggling to do what it used to do; or is breaking down regularly; or is not working at all; you might be wondering whether you should try to repair what you have; or

Unfortunately, boilers don’t last forever. If you’ve noticed your boiler is struggling to do what it used to do; or is breaking down regularly; or is not working at all; you might be wondering whether you should try to repair what you have; or

Common combi fault codes…

Common combi fault codes… Although it’s frustrating when your boiler encounters a problem, it’s important to remember that it’s a complex machine that’s working hard for you around the clock, every day of the year.

Although it’s frustrating when your boiler encounters a problem, it’s important to remember that it’s a complex machine that’s working hard for you around the clock, every day of the year. Although there are many different fault codes that your boiler can display (in different combinations), there’s no need to panic when a code starts flashing.

Although there are many different fault codes that your boiler can display (in different combinations), there’s no need to panic when a code starts flashing. Problems can arise, triggering a fault code, if your boiler is not receiving gas or if the gas pressure is too low.

Problems can arise, triggering a fault code, if your boiler is not receiving gas or if the gas pressure is too low. If your boiler has stopped working when it’s freezing outside, there’s a good chance that your boiler’s

If your boiler has stopped working when it’s freezing outside, there’s a good chance that your boiler’s  It is extremely important that you only perform actions on your boiler if your boiler manual instructs you to do so.

It is extremely important that you only perform actions on your boiler if your boiler manual instructs you to do so. Why is my boiler leaking?

Why is my boiler leaking? Whilst this sounds like a daft question; there are actually a few signs that your boiler is leaking, aside from the obvious puddles of water!

Whilst this sounds like a daft question; there are actually a few signs that your boiler is leaking, aside from the obvious puddles of water! Whilst a leaking boiler is alarming and inconvenient, it isn’t usually dangerous.

Whilst a leaking boiler is alarming and inconvenient, it isn’t usually dangerous. If you’ve spotted a leak, you should follow these simple steps to minimize any further water damage:

If you’ve spotted a leak, you should follow these simple steps to minimize any further water damage: Now that you’ve contained the leak, you might be wondering what the possible cause is. And how expensive a repair is likely to be!

Now that you’ve contained the leak, you might be wondering what the possible cause is. And how expensive a repair is likely to be! Whilst low pressure is a possible sign of a leaking boiler;

Whilst low pressure is a possible sign of a leaking boiler;  If you’ve noticed dripping water coming from underneath your boiler, corroded pipes could well be the culprit.

If you’ve noticed dripping water coming from underneath your boiler, corroded pipes could well be the culprit. Another possible explanation of water dripping from pipe fittings is poor installation.

Another possible explanation of water dripping from pipe fittings is poor installation. Boilers are fitted with a temperature control valve (TCV) which monitors the temperature of the water within the boiler; and stops it from getting too high.

Boilers are fitted with a temperature control valve (TCV) which monitors the temperature of the water within the boiler; and stops it from getting too high. If your boiler is in its golden years; a leak from the bottom of the appliance could be caused by a corroded heat exchanger.

If your boiler is in its golden years; a leak from the bottom of the appliance could be caused by a corroded heat exchanger. Unfortunately,

Unfortunately,  Even if the leak is only slight, it’s important to deal with it quickly. A leak of any size is telling you that there’s a problem, and left untreated, it will only get worse.

Even if the leak is only slight, it’s important to deal with it quickly. A leak of any size is telling you that there’s a problem, and left untreated, it will only get worse. As with anything, prevention is better than cure. The best way to prevent your boiler from springing a leak, is to maintain it with an

As with anything, prevention is better than cure. The best way to prevent your boiler from springing a leak, is to maintain it with an  You could also ask your engineer for advice on whether your heating system would benefit from a

You could also ask your engineer for advice on whether your heating system would benefit from a  Should I leave my heating on?…

Should I leave my heating on?… How many times have you been told as a child (or maybe an adult!) to switch your appliances off; rather than leaving them on standby, to save energy?

How many times have you been told as a child (or maybe an adult!) to switch your appliances off; rather than leaving them on standby, to save energy? According to experts at the Energy Saving Trust, you should only have the heating on when you need it. They’re clear that by doing this, you’ll save energy and therefore

According to experts at the Energy Saving Trust, you should only have the heating on when you need it. They’re clear that by doing this, you’ll save energy and therefore  Whilst the Energy Saving Trust’s argument sounds sensible, it’s not quite as clear-cut as that.

Whilst the Energy Saving Trust’s argument sounds sensible, it’s not quite as clear-cut as that. If you have

If you have  Whilst leaving your heating on can work well if you’ve got decent insulation; it won’t if your home has high levels of heat loss.

Whilst leaving your heating on can work well if you’ve got decent insulation; it won’t if your home has high levels of heat loss. The Greenage say that whether you should leave your heating on all the time or not; depends entirely on how well insulated your home is.

The Greenage say that whether you should leave your heating on all the time or not; depends entirely on how well insulated your home is. If you want to put the two theories to the test, you can.

If you want to put the two theories to the test, you can. As is so often the case in life, the answer to whether or not you should leave your heating on or not; is – it depends!

As is so often the case in life, the answer to whether or not you should leave your heating on or not; is – it depends!

Whether we like it or not, all buildings lose heat. It’s an inescapable fact of science!

Whether we like it or not, all buildings lose heat. It’s an inescapable fact of science! Boiler modulation

Boiler modulation But not all boilers are created equal. How much a boiler can ‘dial down’ its output to, is stated by the manufacturer as a modulation ratio.

But not all boilers are created equal. How much a boiler can ‘dial down’ its output to, is stated by the manufacturer as a modulation ratio. A cycling boiler is a problem because it:

A cycling boiler is a problem because it: One of the main culprits of a cycling boiler is that it’s been oversized.

One of the main culprits of a cycling boiler is that it’s been oversized. We’ve said it before, and we’ll say it again… Your boiler installer is the number one contributor to your heating system’s energy efficiency.

We’ve said it before, and we’ll say it again… Your boiler installer is the number one contributor to your heating system’s energy efficiency. As with all things, prevention is better than cure!

As with all things, prevention is better than cure! 10 common boiler problems…

10 common boiler problems… The dreaded no heating or hot water scenario is probably your biggest fear when it comes to boiler problems, and you’re not alone. Nobody wants to be without heating or hot water, particularly in the winter months.

The dreaded no heating or hot water scenario is probably your biggest fear when it comes to boiler problems, and you’re not alone. Nobody wants to be without heating or hot water, particularly in the winter months. If your home is warm and cosy, but you’re only getting cold water out of your taps, then you have an issue with your hot water supply.

If your home is warm and cosy, but you’re only getting cold water out of your taps, then you have an issue with your hot water supply. If you’ve noticed that your radiators are cold or have cold spots; or are making funny noises; this might indicate that air is trapped inside them, and needs to be released.

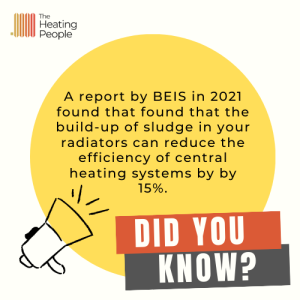

If you’ve noticed that your radiators are cold or have cold spots; or are making funny noises; this might indicate that air is trapped inside them, and needs to be released. Another potential cause of your cold radiators is that they are being blocked by sludge.

Another potential cause of your cold radiators is that they are being blocked by sludge. If you’ve been experiencing boiler problems such as a lack of hot water, it could be that low pressure in your boiler is to blame.

If you’ve been experiencing boiler problems such as a lack of hot water, it could be that low pressure in your boiler is to blame. If you’ve noticed that your boiler is making a strange noise a bit like a kettle boiling – a sort of whistling sound – it’s probably due to a common problem called ‘boiler kettling.’

If you’ve noticed that your boiler is making a strange noise a bit like a kettle boiling – a sort of whistling sound – it’s probably due to a common problem called ‘boiler kettling.’ If it’s not whistling you’re hearing, but something else, this could indicate a different problem to boiler kettling.

If it’s not whistling you’re hearing, but something else, this could indicate a different problem to boiler kettling. Most people use a thermostat to

Most people use a thermostat to  If you’ve got an

If you’ve got an  We hope that you’ve found this trouble shooting guide helpful.

We hope that you’ve found this trouble shooting guide helpful. The benefits of replacing your boiler…

The benefits of replacing your boiler… If you’ve been putting up with a heating system that

If you’ve been putting up with a heating system that If you’re replacing an old boiler with a much newer one; chances are, your new model will give you much more control.

If you’re replacing an old boiler with a much newer one; chances are, your new model will give you much more control. With

With  We’re all starting to appreciate our own social responsibility in finding cleaner and smarter ways of heating our homes. Not just to

We’re all starting to appreciate our own social responsibility in finding cleaner and smarter ways of heating our homes. Not just to  If your old boiler has been temperamental and has been breaking down; you’ll love the peace of mind a new boiler will bring.

If your old boiler has been temperamental and has been breaking down; you’ll love the peace of mind a new boiler will bring. If your old boiler was noisy, you might well notice how much you don’t notice your new one!

If your old boiler was noisy, you might well notice how much you don’t notice your new one! If you switch from a heat-only boiler to a combi boiler; you’ll have hot water on demand because combi’s don’t have a water tank to heat up.

If you switch from a heat-only boiler to a combi boiler; you’ll have hot water on demand because combi’s don’t have a water tank to heat up. If you’re planning on moving home soon, a new A-rated boiler can make your property more attractive to prospective buyers.

If you’re planning on moving home soon, a new A-rated boiler can make your property more attractive to prospective buyers.

5 benefits of your annual service…

5 benefits of your annual service… First and foremost, an annual service is vital in keeping you and your family safe.

First and foremost, an annual service is vital in keeping you and your family safe. Want to keep that nice long guarantee that came with your

Want to keep that nice long guarantee that came with your  Nobody wants to be left without heating and hot water. But it’s often not until misfortune strikes in the form of a breakdown; that you realise how much you rely on your boiler!

Nobody wants to be left without heating and hot water. But it’s often not until misfortune strikes in the form of a breakdown; that you realise how much you rely on your boiler! As well as avoiding breakdowns, an annual service will identify any small problems early; before they turn into larger more expensive ones!

As well as avoiding breakdowns, an annual service will identify any small problems early; before they turn into larger more expensive ones! Replacing a boiler can be costly. So you’ll want to make sure that you get the most out of your investment. To keep your boiler running smoothly for the next 10-15 years, you’ll need to look after it.

Replacing a boiler can be costly. So you’ll want to make sure that you get the most out of your investment. To keep your boiler running smoothly for the next 10-15 years, you’ll need to look after it. A well-maintained and regularly serviced boiler will work more efficiently than a neglected one.

A well-maintained and regularly serviced boiler will work more efficiently than a neglected one. Landlords are under a legal duty to have an annual safety check on all gas appliances and flues.

Landlords are under a legal duty to have an annual safety check on all gas appliances and flues. A gas safety check assesses the basic safety of gas appliances in your home. Its purpose is to ensure everything is working correctly and is safe.

A gas safety check assesses the basic safety of gas appliances in your home. Its purpose is to ensure everything is working correctly and is safe. To keep your boiler operating safely and efficiently; it’s critical that you have it regularly serviced by a Gas Safe registered engineer.

To keep your boiler operating safely and efficiently; it’s critical that you have it regularly serviced by a Gas Safe registered engineer. Although we only tend to only think about our boilers during the winter, when the weather turns colder; you rely on your boiler all year round.

Although we only tend to only think about our boilers during the winter, when the weather turns colder; you rely on your boiler all year round. It’s a legal requirement for landlords to have their gas appliances serviced every year by a Gas Safe engineer.

It’s a legal requirement for landlords to have their gas appliances serviced every year by a Gas Safe engineer. To sum up… you wouldn’t dream of driving a car without a valid MOT, and the same is true of your boiler.

To sum up… you wouldn’t dream of driving a car without a valid MOT, and the same is true of your boiler.